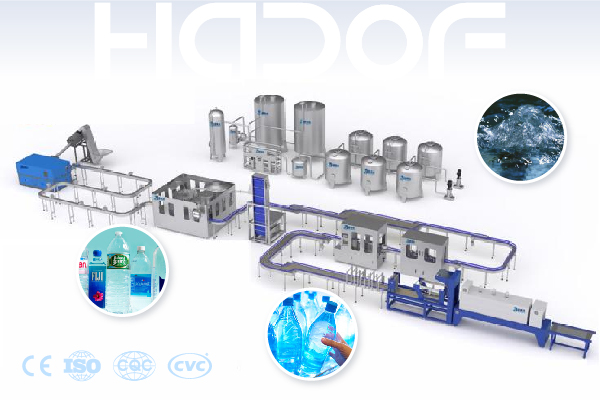

Our drinking water production line is an advanced automated system that covers the entire production process, from water treatment, filtration, and mineralization, to filling, capping, labeling, and packaging. Designed for high efficiency and flexibility, it supports various bottle sizes and types. The system ensures top-tier water quality and hygiene standards while reducing production costs. With state-of-the-art technology, this line is ideal for both small and large-scale operations, meeting international food safety and environmental regulations for sustainable and reliable water production.

Capacity:2000-42000 bottles/hour

Bottle capacity Range: 200มล. – 2000มล.

Bottle Type Support: PET bottles, glass bottles, aluminum cans

Sterilization Method: Pasteurization/UHT

Equipment Material:SUS304/316 food grade stainless steel

Applicable beverage types: Water, Tea Drinks, Juice, Functional Drinks, Soda, etc.

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

อีเมล: info@hadofmachinery.com

Product Parameters

| Capacity | 2000-42000 bottles/hour | Equipment power | 80-150kW (depending on production line configuration) |

| Bottle type support | PET bottles, glass bottles, aluminum cans | Equipment material | SUS304/316 food grade stainless steel |

| Bottle capacity range | 200มล. – 2000มล. | Filling accuracy | ±1% |

| Applicable beverage types | Purified water, mineral water, soda water,sparkling water, functional beverages | Control system | PLC automatic control, touch screen operation |

| Sterilization method | Pasteurization/UHT | Production line length | 15m – 30m |

| Filling method | Hot filling/Aseptic filling | Packaging type | Carton packaging, plastic packaging |

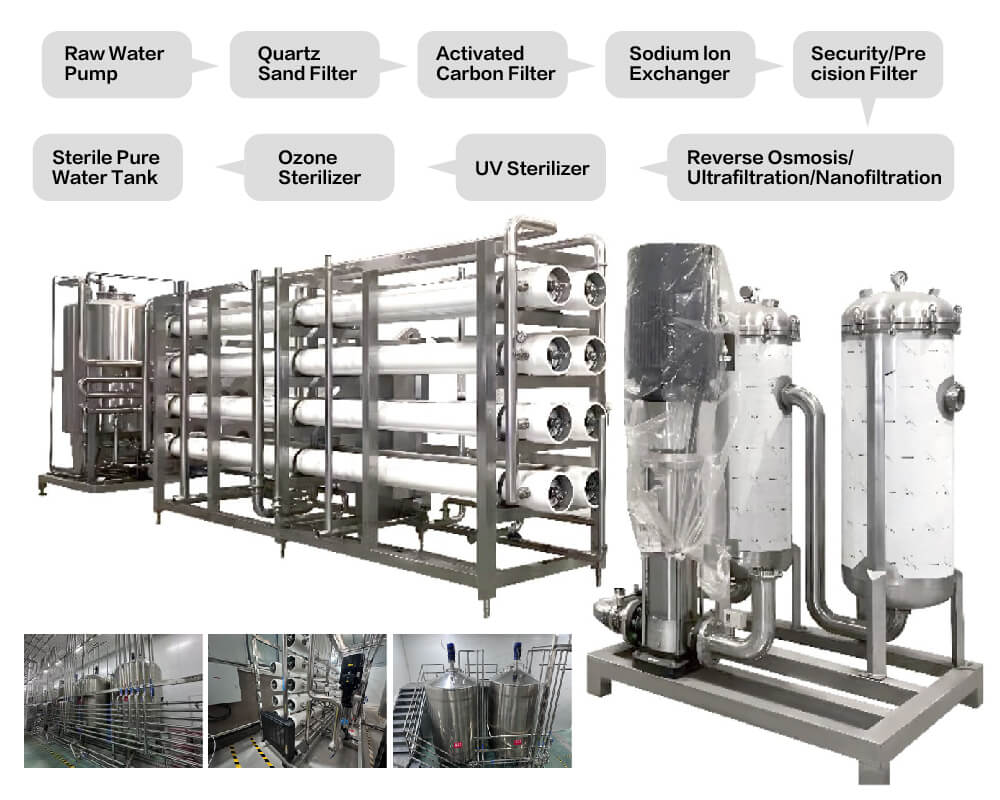

Water Treatment System

Water Treatment System

preparation Blowing Bottle

Blowing Bottle Filling

Filling Labeling

Labeling Packaging

Packaging Palletizing

Palletizing

Water Treatment System

It can remove impurities, reduce organic matter content, remove residual chlorine, kill and remove microorganisms, and adjust water quality components to ensure the clarity, taste, safety of drinking water and retain beneficial minerals.

Fully Automatic Bottle Blowing Machine

The preform is heated and softened, and then blown into shape using high-pressure air to ensure bottle quality; the bottle output can reach 2500BPH-6000BPH, fully meeting customer needs.

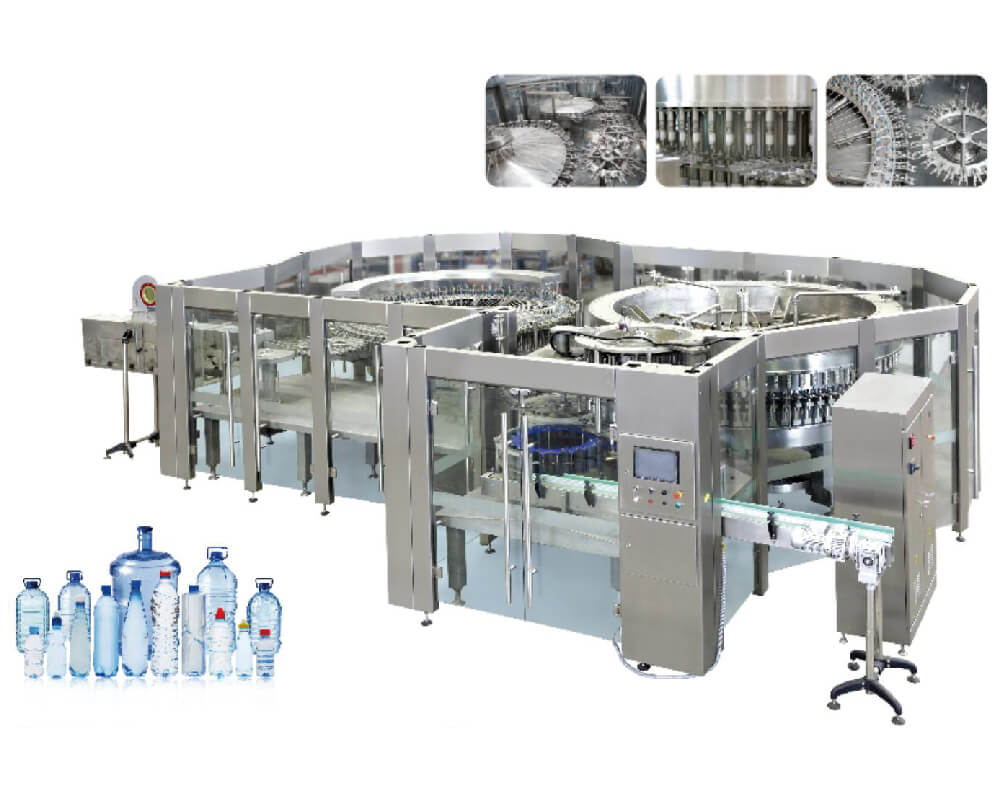

XGF Bottled Drinking Water Filling Line

The production line covers a complete and coherent series of process flows from empty bottle conveying, cleaning, filling to capping, with an output of 8000BPH-48000BPH.

Sleeve Labeling Machine / Labeling Machine

Sleeve Labeling Machine :The labels are cut and formed into cylindrical labels and then put on the bottles at high speed to meet large-scale production.

labeling Machine:It adopts local glue application method, with small glue consumption, low operating cost, and production capacity up to 30,000 BPH

Fully Automatic Film Wrapping Machine

Equipped with a touch screen operation panel, adapted to different product sizes and packaging requirements, to achieve efficient packaging

Palletizer:

The palletizer can control the stacking process more accurately, avoiding material waste caused by irregular or damaged stacking, effectively improving production efficiency and reducing labor costs. It is a key equipment to ensure safety and product quality.