Carbonated beverages are drinks made by adding carbon dioxide gas to beverages. They have a unique bubbly taste and a refreshing flavor. They are available in a wide variety, including cola, Sprite, and fruit-flavored soda, and are loved by consumers around the world. Carbonated beverages not only bring stimulation and pleasure in taste, but are also often paired with fruit flavors, herbal ingredients, or functional formulas to meet the needs of different groups of people.

Capacity: 2000-42000 bottles/hour

Filling Accuracy: ≤±5mm (Liquid Level Positioning)

Applicable Bottle Type: Round or Square

Applicable Cap Type: Plastic Screw Cap

Bottle Rinsing Water Pressure (MPa):0.2~0.25

PET Bottle Specifications: Bottle Diameter Ф50~Ф100, Bottle Height 150mm~330mm

Applicable beverage types: water, tea drinks, น้ำผลไม้, functional drinks, water, โซดา, etc.

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

อีเมล: info@hadofmachinery.com

Parameter

| Technical Parameters | HDF8-8-4 | HDF14-12-5 | HDF16-16-5 | HDF20-20-6 | HDF24-24-8 | HDF32-32-10 | HDF40-40-12 | HDF50-50-15 |

| Production Capacity (500ml/B/H) | 2000-3000 | 3000-4000 | 4000-5000 | 5000-7000 | 8000-10000 | 10000-12000 | 14000-15000 | 16000-18000 |

| Specifications | 60π | 50π | 50π | 50π | 45π | 45π | 40π | 36π |

| Bottle Rinse Usage (Kg/h) | 500 | 600 | 700 | 800 | 1500 | 1800 | 2500 | 3000 |

| Air Source Pressure (MPa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Air Consumption (m³/min) | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.55 |

| Total Power (Kw) | 2.5 | 3 | 3.3 | 3.8 | 4.2 | 5.6 | 6.4 | 9.8 |

| Dimensions (L×W×H) (mm) | 1950×1450×2350 | 2260×1600×2350 | 2350×1900×2350 | 2900×2200×2400 | 3300×2300×2400 | 4100×2850×2400 | 4250×3200×2400 | 5750×3750×2400 |

| Total Weight (Kg) | 2500 | 2800 | 3000 | 4000 | 5000 | 6500 | 8000 | 9000 |

Water Treatment

Water Treatment Blow Molding

Blow Molding Mixing

Mixing Filling

Filling Cooling

Cooling Labeling

Labeling Packaging

Packaging Palletizing

Palletizing

1. Water Treatment System:

Water treatment is a critical step to ensure the quality of the soda water. The production line uses advanced reverse osmosis equipment for deep purification.

Multiple steps including sedimentation, filtration, and disinfection ensure water quality.

– Organic matter, metal oxides, suspended solids, bacteria, and colloids are removed from the water.

– After treatment, the water meets the required purity standards for soda water production.

– The purified water is now ready for use in the mixing process.

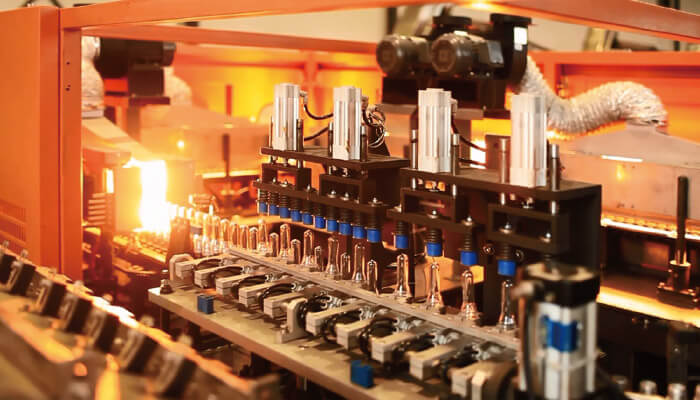

2. Blowing Equipment:

– The preforms enter the blow molding machine through the conveying system.

– The preforms are preheated in the oven and heated evenly.

– The preforms are formed and output under the action of high-pressure gas.

3. Blending, Cooling And Mixing Systems:

– Mixing of water, syrup and CO2.

– Sugar dissolving pot and blending tank for making syrup.

– Beverage mixer for filtering and mixing.

– Vacuum degassing and proportioning system for optimized mixing.

– CO2 jet technology for improved taste.

– Plate heat exchanger for cooling to 0℃~3℃.

– Carbonation is done in CO2 mixing tank.

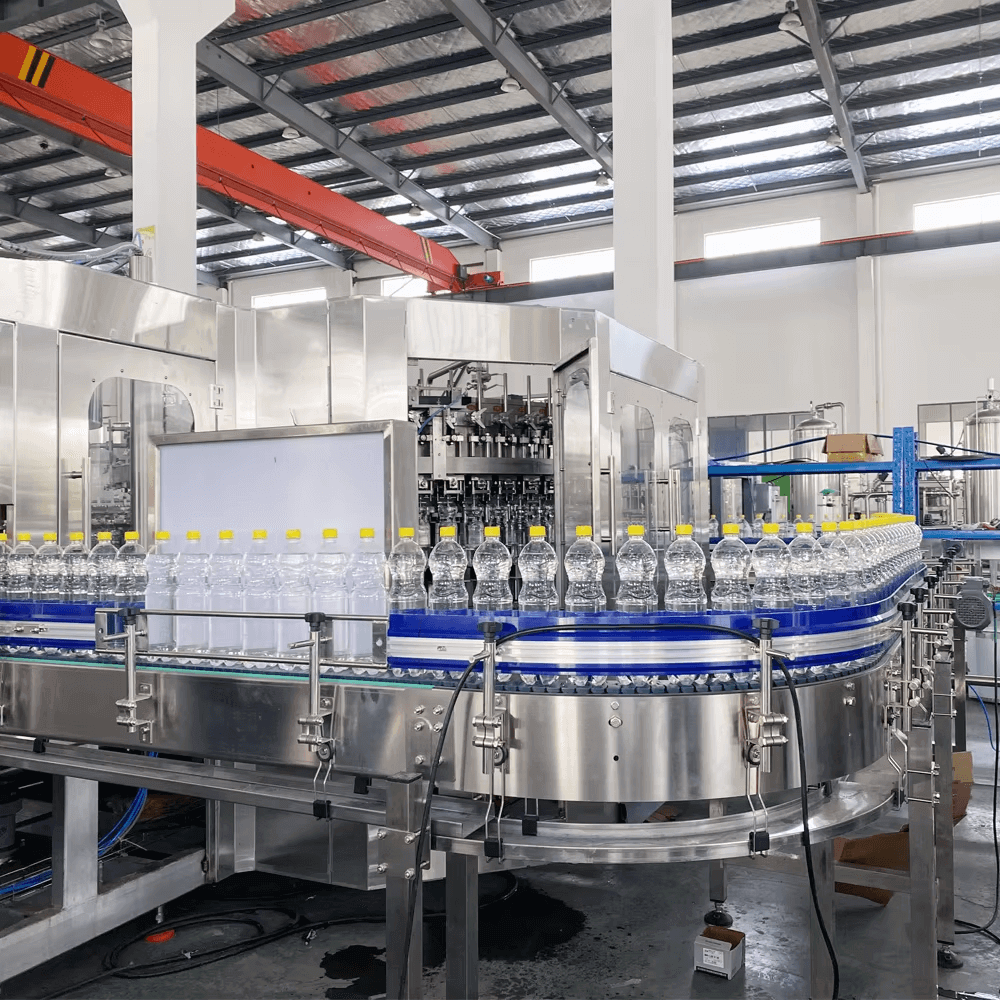

4.Filling system:

– The material enters the filling machine cylinder and the flow is controlled by a pneumatic diaphragm valve.

– Plastic bottles: air conveying device and hanging bottleneck method are used for bottle washing, isobaric filling and capping.

– Glass bottles: air conveying and water spray cleaning, isobaric filling, electromagnetic capping.

– Cans: After normal pressure filling, the capping system completes pre-sealing and actual sealing.

5. Spray cooling system

The spray cooling system sprays a cooling liquid onto the filled bottles to bring the temperature inside the bottles down to a suitable level. This helps prevent the leakage of carbon dioxide gas, ensuring the stability and quality of the products.

6. Coding and labeling machine

Print the production date, batch number and other information on the bottle to ensure the traceability of each bottle of product.

According to customer requirements and market demand, we provide better solutions for the final product packaging design, such as PVC sleeve labels, BOPP hot glue labels, self-adhesive labels, cold glue paper labels.

7.Film wrapping machine

The film wrapping machine is used to wrap the labeled bottles in film, ensuring the safety and hygiene of the products during transportation and storage. It protects the bottles from external contamination and helps maintain the products’ condition during long-distance shipping.

8. Robotic palletizer

The robotic palletizer automatically stacks the packaged bottles onto pallets in a predetermined pattern. This fully automated process streamlines the packaging procedure, ensuring efficient preparation for final shipment and reducing the need for manual labor.