The bottled tea production line is a fully automated system that covers tea extraction, mixing, sterilization, filling, capping, and packaging. Designed for high efficiency and precision, it ensures consistent product quality and safety. Advanced technology and hygienic processes guarantee freshness and flavor retention, making it ideal for large-scale production of various bottled tea beverages. This production line is suitable for green tea, black tea, fruit tea, and herbal tea, meeting diverse market demands.

Capacity:2000-42000 bottles/hour

Bottle capacity range: 200มล. – 2000มล.

Bottle type support: PET bottles, glass bottles, aluminum cans

Sterilization method: Pasteurization/UHT

Filling method: Hot filling/aseptic filling

Applicable beverage types: water, tea drinks, น้ำผลไม้, functional drinks, โซดา, etc.

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

อีเมล: info@hadofmachinery.com

Parameter

| Capacity | 2000-42000 bottles/hour | Equipment power | 80-150kW (depending on production line configuration) |

| Bottle type support | PET bottles, glass bottles, aluminum cans | Equipment material | SUS304/316 food grade stainless steel |

| Bottle capacity range | 200มล. – 2000มล. | Filling accuracy | ±1% |

| Applicable beverage types | Tea drinks, น้ำผลไม้, functional drinks, water, โซดา, etc. | Control system | PLC automatic control, touch screen operation |

| Sterilization method | Pasteurization/UHT | Packaging type | Carton packaging, plastic packaging |

| Filling method | Hot filling/aseptic filling | Production line length | 15m – 30m |

Raw material

Raw material

preparation Tea Extraction

Tea Extraction Mixing

Mixing Homogenization

Homogenization Sterilization

Sterilization Filling

Filling Cooling

Cooling Labeling

Labeling Packaging

Packaging

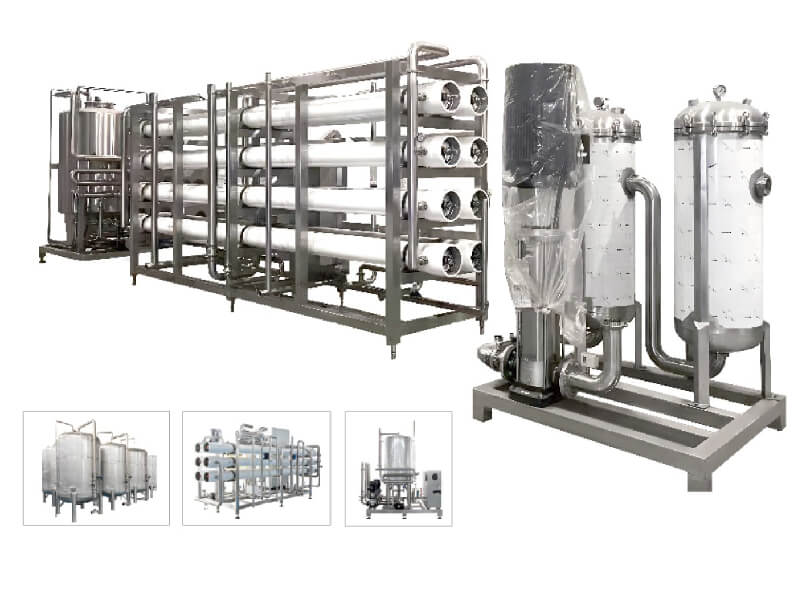

Tea selection: Select green tea, black tea, oolong tea and other teas according to the product formula. Ingredient preparation: Prepare water, sugar, juice concentrate, natural flavors or other additives according to the formula. Water treatment: Purify water through water treatment equipment to ensure that the production water meets the hygiene standards.

Use the tea extraction system to mix tea leaves with hot water in proportion and extract the essence of tea soup at a set time and temperature. Control parameters: extraction time, temperature (usually 80℃ to 90℃) and water-to-tea ratio.

Mix the tea liquid with other ingredients (such as syrup, น้ำผลไม้, honey) in proportion in the mixing tank. The ingredients need to be stirred evenly during the mixing process, and the sugar content and pH value of the mixture should be tested at the same time.

Use a homogenizer to process the mixture under high pressure to disperse the ingredients evenly, prevent stratification and improve the taste.

Ultra-high temperature sterilization (UHT) of tea. Ultra-high temperature sterilization: The temperature can reach 135℃-150℃, which can sterilize more thoroughly and extend the shelf life.

The hot filling line is used to automatically and quantitatively fill the processed tea beverage into sterilized bottles. The bottles are sealed by a capping machine to ensure that the bottle mouth is free of contamination. The material of the bottle is usually PET, glass or aluminum cans.

The filled bottles are cooled quickly through the cooling tunnel to prevent high temperature from affecting the product flavor and enhance the strength of the bottle. After cooling to room temperature, they enter the next stage.

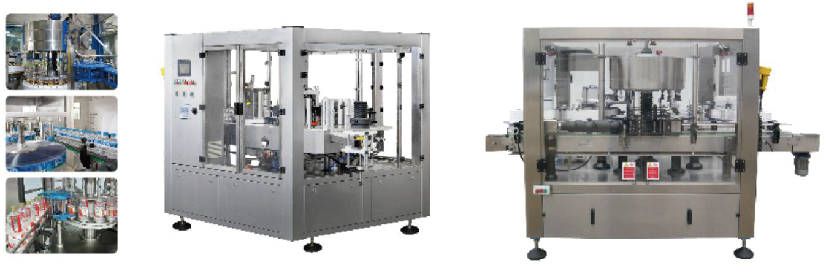

The bottle body is pasted with a brand label through a labeling machine, and the production date, batch number and other information are marked through an inkjet printer.

Bottled tea is divided into boxes or sealed by automatic packaging machines for easy transportation and sales. Packaging methods include cartons, plastic shrink films, etc., which can be selected according to market demand.