Soda water is a refreshing drink rich in carbon dioxide bubbles. It can be enjoyed alone or mixed with cocktails and juices to enhance flavor. It aids digestion, relieves greasiness, and refreshes the mind, making it popular among consumers. With growing demand for healthy drinks, natural and sugar-free soda water has become a top choice for a healthy lifestyle.

Capacidade:2000-42000 garrafas/hora

Filling Accuracy: ≤±5mm (Liquid Level Positioning)

Applicable Bottle Type:Round or Square

Applicable Cap Type: Plastic Screw Cap

Bottle Rinsing Water Pressure (MPa):0.2~0.25

PET Bottle Specifications: Bottle Diameter Ф50~Ф100, Bottle Height 150mm~330mm

Tipos de bebidas aplicáveis: water, bebidas de chá, suco, bebidas funcionais, water, refrigerante, etc..

Tel: +86 371-86582811

MOB & Whatsapp: +86 15239453015

E-mail: info@hadofmachinery.com

Parameter

| Technical Parameters | HDF8-8-4 | HDF14-12-5 | HDF16-16-5 | HDF20-20-6 | HDF24-24-8 | HDF32-32-10 | HDF40-40-12 | HDF50-50-15 |

| Production Capacity (500ml/B/H) | 2000-3000 | 3000-4000 | 4000-5000 | 5000-7000 | 8000-10000 | 10000-12000 | 14000-15000 | 16000-18000 |

| Specifications | 60π | 50π | 50π | 50π | 45π | 45π | 40π | 36π |

| Bottle Rinse Usage (Kg/h) | 500 | 600 | 700 | 800 | 1500 | 1800 | 2500 | 3000 |

| Air Source Pressure (MPa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Air Consumption (m³/min) | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.55 |

| Total Power (Kw) | 2.5 | 3 | 3.3 | 3.8 | 4.2 | 5.6 | 6.4 | 9.8 |

| Dimensions (L×W×H) (mm) | 1950×1450×2350 | 2260×1600×2350 | 2350×1900×2350 | 2900×2200×2400 | 3300×2300×2400 | 4100×2850×2400 | 4250×3200×2400 | 5750×3750×2400 |

| Total Weight (Kg) | 2500 | 2800 | 3000 | 4000 | 5000 | 6500 | 8000 | 9000 |

Raw Materials

Raw Materials Water Treatment

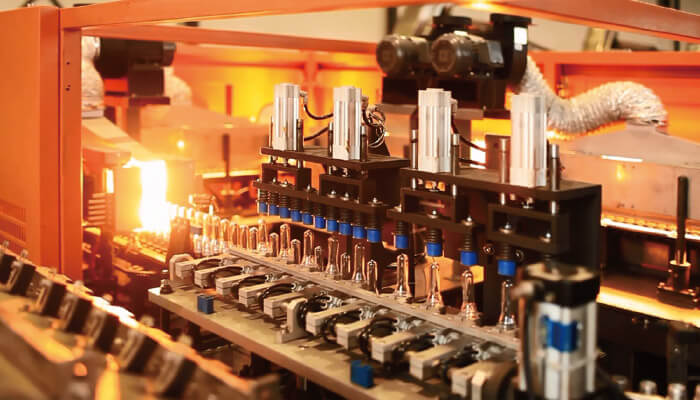

Water Treatment Blow Molding

Blow Molding Mixing

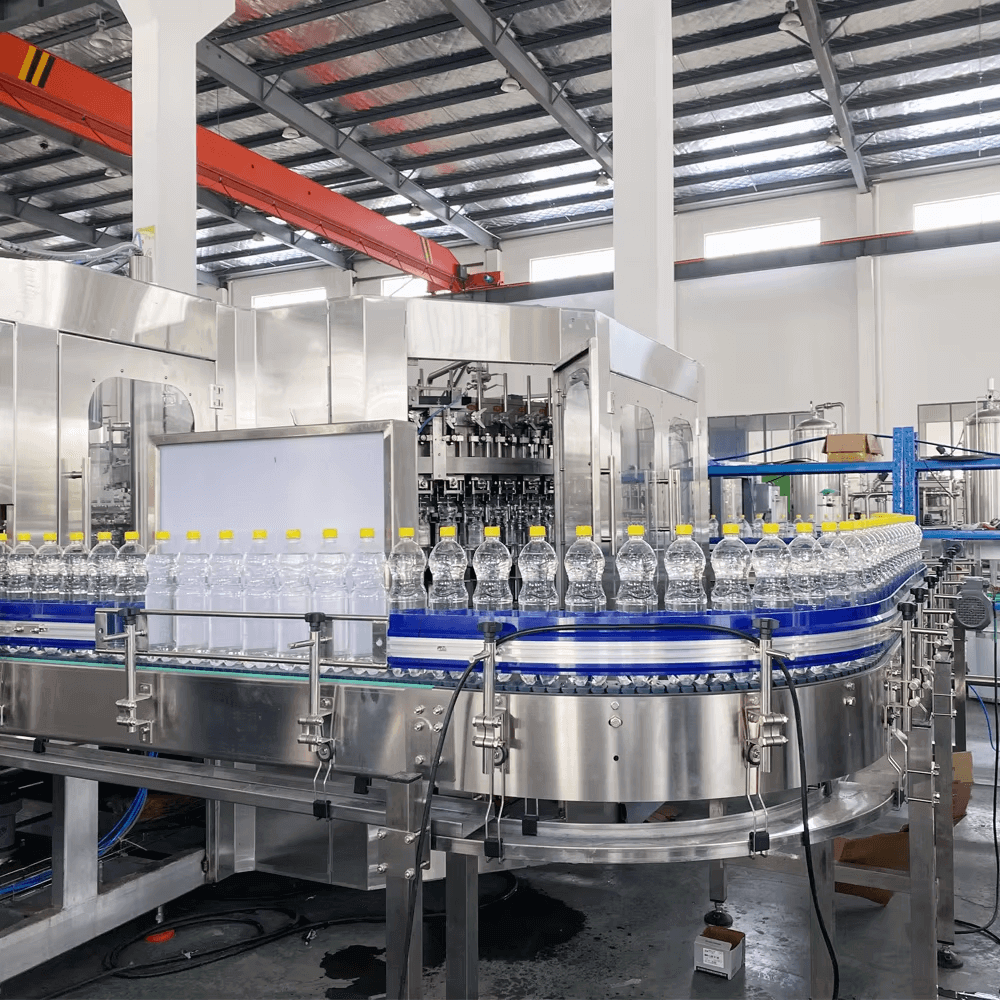

Mixing Filling

Filling Cooling

Cooling Labeling

Labeling Packaging

Packaging Paletização

Paletização

1.Preparation of Raw Materials:

The preparation of raw materials involves obtaining purified water, sodium bicarbonate, and various additives or flavorings.

– Purified water is treated using reverse osmosis equipment to remove impurities, bacteria, and microorganisms.

– Sodium bicarbonate is measured and prepared according to the production formula, while additives and flavorings are prepared as required for the final product.

– These raw materials are organized and ready for the next steps in the production process.

2. Water Treatment System:

Water treatment is a critical step to ensure the quality of the soda water. The production line uses advanced reverse osmosis equipment for deep purification.

Multiple steps including sedimentation, filtração, and disinfection ensure water quality.

– Organic matter, metal oxides, suspended solids, bacteria, and colloids are removed from the water.

– After treatment, the water meets the required purity standards for soda water production.

– The purified water is now ready for use in the mixing process.

3.Bottle Cleaning, Inspection, and Air Conveyor System

The empty bottles are first cleaned and disinfected to remove contaminants, ensuring they are hygienic and ready for the filling process.

After cleaning, each bottle is carefully inspected to meet the necessary standards. The cleaned bottles are then transferred to the filling machine via air conveyors, ensuring smooth, efficient, and damage-free transportation.

The air conveyor system enhances operational efficiency by precisely aligning and moving the bottles to the next production stage while preventing any potential contamination.

4. Mixing and Flavoring:

Treated water is combined with precisely measured sodium bicarbonate to form the base liquid for soda water.

– High-speed stirring equipment ensures full integration of the components.

– Flavorings or essences are added as needed to enhance the taste of the soda water.

– The final product is carefully blended to achieve the desired taste and quality.

– The soda water is now ready for packaging and distribution.

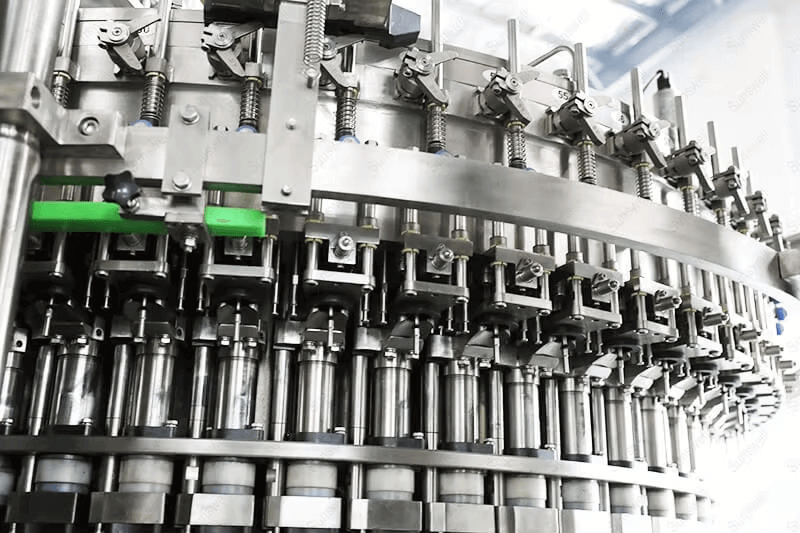

5.Filling system:

– The material enters the filling machine cylinder and the flow is controlled by a pneumatic diaphragm valve.

– Plastic bottles: air conveying device and hanging bottleneck method are used for bottle washing, isobaric filling and capping.

– Glass bottles: air conveying and water spray cleaning, isobaric filling, electromagnetic capping.

– Cans: After normal pressure filling, the capping system completes pre-sealing and actual sealing.

6. Spray cooling system

The spray cooling system sprays a cooling liquid onto the filled bottles to bring the temperature inside the bottles down to a suitable level. This helps prevent the leakage of carbon dioxide gas, ensuring the stability and quality of the products.

7. Coding and labeling machine

Print the production date, batch number and other information on the bottle to ensure the traceability of each bottle of product.

According to customer requirements and market demand, we provide better solutions for the final product packaging design, such as PVC sleeve labels, BOPP hot glue labels, self-adhesive labels, cold glue paper labels.

8.Film wrapping machine

The film wrapping machine is used to wrap the labeled bottles in film, ensuring the safety and hygiene of the products during transportation and storage. It protects the bottles from external contamination and helps maintain the products’ condition during long-distance shipping.

9. Robotic palletizer

The robotic palletizer automatically stacks the packaged bottles onto pallets in a predetermined pattern. This fully automated process streamlines the packaging procedure, ensuring efficient preparation for final shipment and reducing the need for manual labor.