Efficient production solutions for beverages with high quality and flexibility.

Beverage Lines

Efficiently produces water, wine, soft drinks, fruit juices, etc. Advanced automation, precise control, and flexible packaging options, ensuring high productivity and product quality. Ideal for scaling operations and meeting diverse market demands.

Water lines

Purified Water, Mineral Water, Sparkling Water, Functional Water, Etc.

Filling Lines

Bottle Filling, Can Filling, Bag Filling, Etc.

Carbonated soft drinks lines

Coke, Sprite, Soda, Sparkling Mixed Drinks, Cocktails, Flavored Waters, Etc.

Coffee & tea drinks lines

Coffee, Iced Tea, Green Tea, Black Tea, Oolong Tea, Etc.

Daily Chemical Products Lines

Laundry Detergent, Dish Soap,Shampoo, Disinfectant, Conditioner, Etc.

Sauces & Dressings Lines

Soy Sauce, Tomato Sauce, Vinegar, Sugar Water, Chili Sauce, Etc.

Edible Oil Lines

Peanut Oil,Palm Oil, Blended Oil, Lubricating Oil, Etc.

Fruit Juice Lines

Orange Juice, Apple Juice, Grape Juice, Carrot Juice, Mango Juice, Etc.

Carbonated Drink Production Line

Carbonated beverages are drinks made by adding carbon dioxide gas to beverages. They have a unique bubbly taste and a refreshing flavor. They are available in a wide variety, including cola, Sprite, and fruit-flavored soda, and are loved by consumers around the world. Carbonated beverages not only bring stimulation and pleasure in taste, but are also often paired with fruit flavors, herbal ingredients, or functional formulas to meet the needs of different groups of people. Capacity: 2000-42000 bottles/hourFilling Accuracy: ≤±5mm (Liquid Level Positioning)Applicable Bottle Type: Round or SquareApplicable Cap Type: …

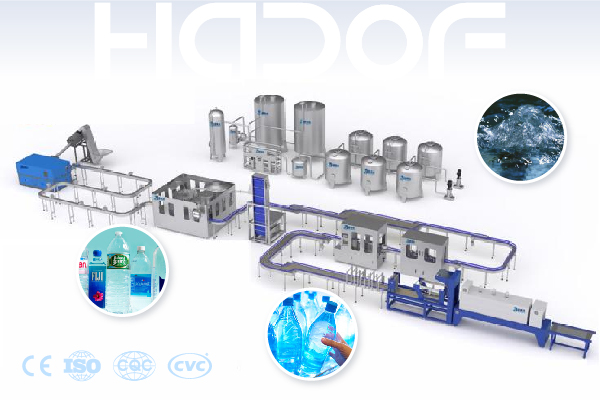

Drinking Water Production Line

Our drinking water production line is an advanced automated system that covers the entire production process, from water treatment, filtration, and mineralization, to filling, capping, labeling, and packaging. Designed for high efficiency and flexibility, it supports various bottle sizes and types. The system ensures top-tier water quality and hygiene standards while reducing production costs. With state-of-the-art technology, this line is ideal for both small and large-scale operations, meeting international food safety and environmental regulations for sustainable and reliable water production. Capacity:2000-42000 bottles/hourBottle capacity Range: 200ml – 2000mlBottle Type Support: PET …

Soda Water Production Line

Soda water is a refreshing drink rich in carbon dioxide bubbles. It can be enjoyed alone or mixed with cocktails and juices to enhance flavor. It aids digestion, relieves greasiness, and refreshes the mind, making it popular among consumers. With growing demand for healthy drinks, natural and sugar-free soda water has become a top choice for a healthy lifestyle. Capacity:2000-42000 bottles/hourFilling Accuracy: ≤±5mm (Liquid Level Positioning)Applicable Bottle Type:Round or SquareApplicable Cap Type: Plastic Screw Cap Bottle Rinsing Water Pressure (MPa):0.2~0.25PET Bottle Specifications: Bottle Diameter Ф50~Ф100, Bottle Height 150mm~330mmApplicable beverage types: …

Sparkling Water Production Line

Sparkling water, also known as soda water, carbonated water or mineral sparkling water, is beverage that contains dissolved carbon dioxide. Carbon dioxide dissolves in water under pressure, forming carbonic acid. When the pressure is released, the carbon dioxide gas will gradually escape from the water, forming bubbles. Sparkling water can be naturally generated or artificially produced. Artificially produced sparkling water is usually made by adding carbon dioxide to water. Some also have salt and minerals added to improve the taste. Brand Hadof Raw Materials pure water, CO2, etc. Capacity 5T/D-1000T/D …

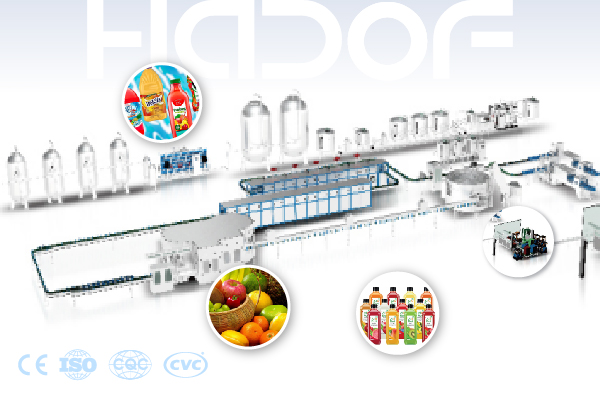

Juice Production Line

Our juice production line is a state-of-the-art system designed to efficiently produce high-quality fruit juices. It includes all essential stages, from fruit washing, sorting, and pulping, to juice extraction, filtration, pasteurization, and bottling. The line is fully automated, ensuring consistent quality and high productivity. With advanced technology, it meets international food safety standards, offering flexibility to produce a wide range of fruit juices in various packaging formats. Ideal for both small and large-scale production, our juice production line guarantees optimal performance and energy efficiency. Capacity:2000-42000 bottles/hourBottle Capacity Range: 200ml – …

Bottled Tea Production Line

The bottled tea production line is a fully automated system that covers tea extraction, mixing, sterilization, filling, capping, and packaging. Designed for high efficiency and precision, it ensures consistent product quality and safety. Advanced technology and hygienic processes guarantee freshness and flavor retention, making it ideal for large-scale production of various bottled tea beverages. This production line is suitable for green tea, black tea, fruit tea, and herbal tea, meeting diverse market demands. Capacity:2000-42000 bottles/hourBottle capacity range: 200ml – 2000mlBottle type support: PET bottles, glass bottles, aluminum cansSterilization method: Pasteurization/UHTFilling …