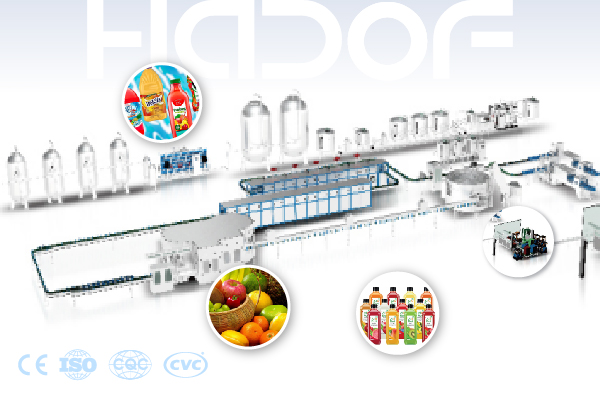

Our juice production line is a state-of-the-art system designed to efficiently produce high-quality fruit juices. It includes all essential stages, from fruit washing, sorting, and pulping, to juice extraction, filtration, pasteurization, and bottling. The line is fully automated, ensuring consistent quality and high productivity. With advanced technology, it meets international food safety standards, offering flexibility to produce a wide range of fruit juices in various packaging formats. Ideal for both small and large-scale production, our juice production line guarantees optimal performance and energy efficiency.

Capacity:2000-42000 bottles/hour

Bottle Capacity Range: 200ml – 2000ml

Bottle Type Support: PET bottles, glass bottles, aluminum cans

Sterilization Method: Pasteurization/UHT

Equipment Material:SUS304/316 food grade stainless steel

Applicable Beverage Types:Juice Drinks, Freshly Squeezed Juice, Mixed Juice Drinks, Functional Juice, Fruit Juice Concentrate

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

Email: info@hadofmachinery.com

Product Parameter

| Capacity | 2000-42000 bottles/hour | Equipment power | 80-150kW (depending on production line configuration) |

| Bottle type support | PET bottles, glass bottles, aluminum cans | Equipment material | SUS304/316 food grade stainless steel |

| Bottle capacity range | 200ml – 2000ml | Filling accuracy | ±1% |

| Applicable beverage types | Juice,tea drinks, functional drinks, etc. | Control system | PLC automatic control, touch screen operation |

| Sterilization method | Pasteurization/UHT | Production line length | 15m – 30m |

| Filling method | Hot filling/Aseptic filling | Packaging type | Carton packaging, plastic packaging |

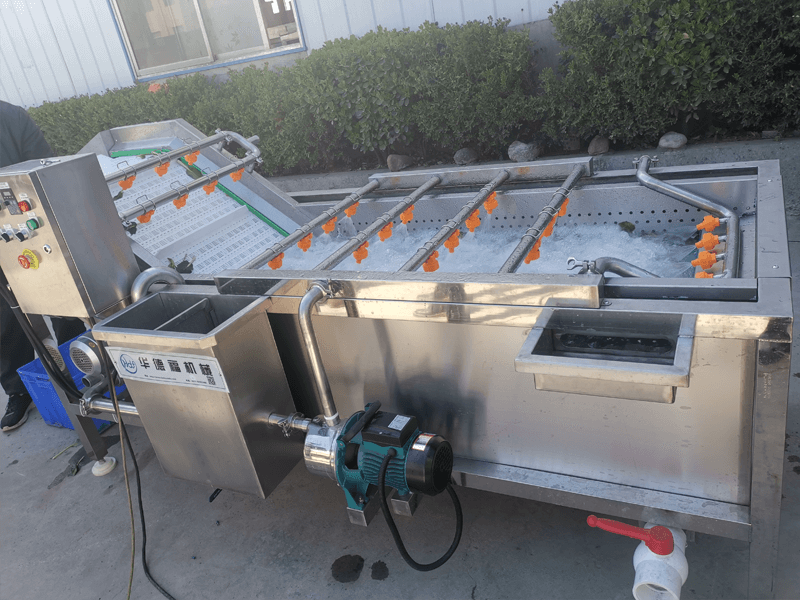

Washing

Washing

preparation Juicing

Juicing Concentration

Concentration Auxiliary

Auxiliary  Sterilization

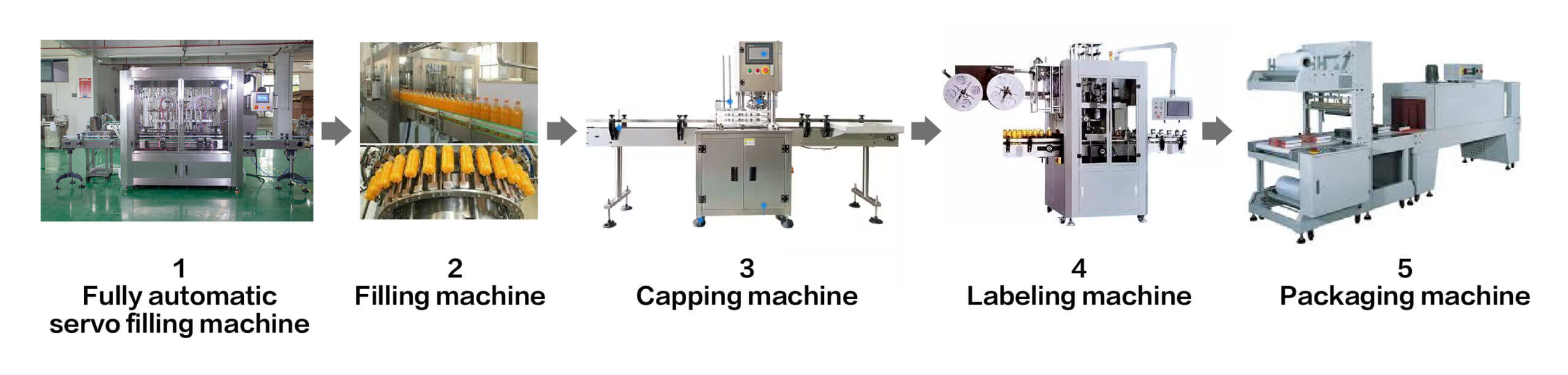

Sterilization Filling and Packaging

Filling and Packaging Palletizing

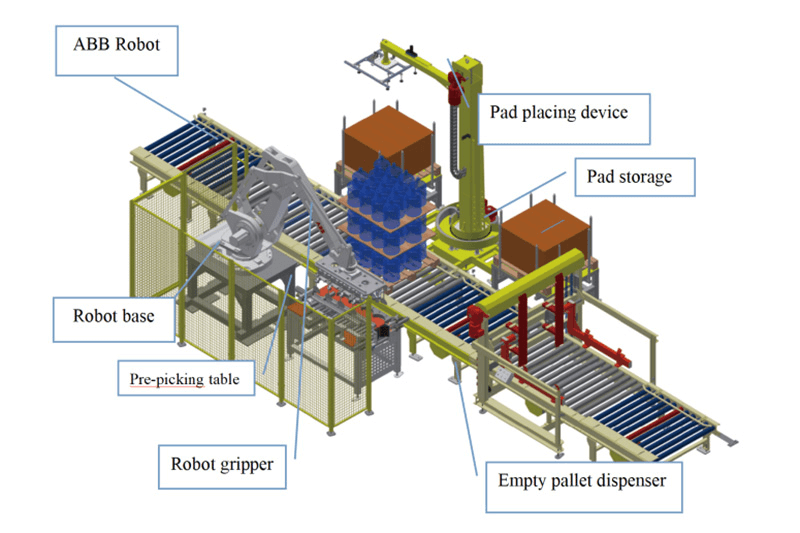

Palletizing

In order to ensure the hygiene and safety of juice production, fruits need to go through automatic cleaning and peeling equipment to remove surface dust and pesticide residues. Some fruits (such as oranges, lemons, etc.) need to remove the peel to remove possible bitterness, impurities or parts that affect the taste.

After washing and peeling, the fruits enter the crushing equipment for crushing and become pulp. This step uses crusher and pulping equipment.

The crushed fruit pulp enters the juicer for juice extraction. Juicing methods can be selected from centrifugal juicing, spiral juicing, pressure juicing, etc. Different fruits may use different juicing technologies.

Juicing process: The purpose of juicing is to extract the liquid part from the pulp, and the remaining pomace will be separated. The liquid in the juicing process will enter the filtration and slag removal stage for clarification.

For some fruit juice products, a concentration process is required to remove water and reduce the volume for easy storage and transportation. Concentration usually uses an evaporator or reverse osmosis equipment. The concentrated juice evaporates water through decompression, heating and other methods, while retaining most of the fruit flavor and nutrients.

To ensure a balanced taste, the sweetness and acidity of the juice are usually adjusted as needed. Some juices may be added with vitamins (such as vitamin C, calcium and other minerals) or other functional ingredients to increase their nutritional value.

In order to extend the shelf life of juice, juice is usually sterilized by heat to eliminate microorganisms in the juice while retaining the nutrients of the juice to the greatest extent. For some high-end juices, low-temperature sterilization technology may be used, such as ultraviolet sterilization and ozone disinfection, to avoid high temperature damage to the nutrients and taste of the juice.

To avoid contamination, the juice is filled through an aseptic filling system.

Then a capping machine is used to quickly seal to prevent air and bacteria from entering. Common packaging forms include bottles, bags, cans, etc. The packaging materials can be PET bottles, glass bottles, aluminum foil bags, etc.

Then use a labeling machine or a sleeve labeling machine to affix labels with information such as production date and shelf life written on them.

Finally, a packaging machine is used for packaging

Palletizers can improve production efficiency, save labor costs, increase output, and improve storage and transportation efficiency.